Our Services

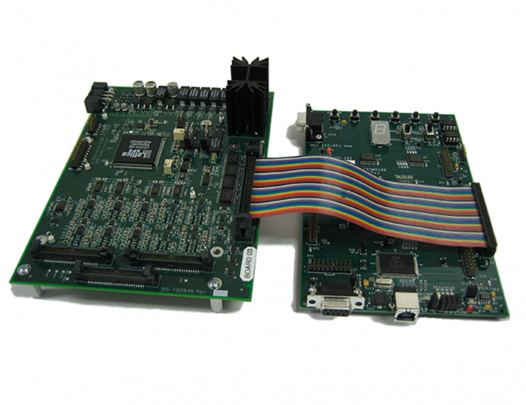

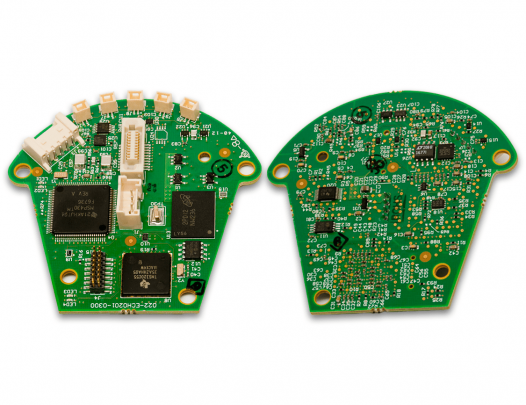

Hardware Design

What We Do

From concept to volume production

PCB Layout & Design

Designing high-speed, high-density digital, analog, and RF PCBs for diverse applications.

Schematic Capture

From concept to production, we create precise schematics that drive reliable electronic hardware development.

First-Time-Right PCBs

Delivering successful first-build PCB designs with high signal accuracy and layout precision.

Software & FPGA Design

Creating embedded software and FPGA solutions alongside hardware development efforts.

Advanced PCB Analysis

Providing peer reviews, signal integrity modeling, and PDN analysis upon client request.

Manufacturing Readiness

Ensuring a smooth transition from prototyping to volume production and certification.

Our Experience

PCB Design Expertise

- High-speed, multi-layer digital PCB designs (SMT, SMT/TH and HDI), e.g. Fibre channel FC8, FDR InfiniBand, PCIe 4.0, HDMI 2.0, SATA 2.0, XAUI, USB3.2, Thunderbolt, DisplayPort, MIPI CSI-2, 25GbE, DDR4

- High-speed SerDes circuits up to 25GHz (single lane)

- High-speed MIPI CSI-2 circuits for multiple cameras / images

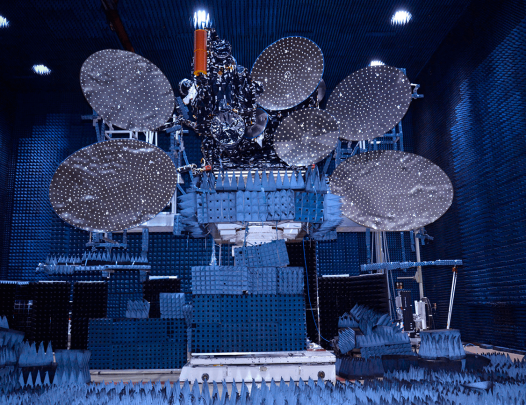

- Radio frequency (RF) PCB designs

- High-speed data bus memories, e.g. DDR2/3/4/5/6, QSPI, NOR/NAND Flash, SRAM, proprietary buses

- High-speed optical signal circuits, e.g. ROSA, TOSA and SFP28 (25Gbps)

- High-density and high pin-count designs in advanced PCB technology, e.g. microvias, via-in-pad, ultra-fine pitch BGAs, ‘first-time-right’ and DFM methodologies

- Any-layer HDI PCB for boards with ultra-fine and high pin-count packages

- Low-level analog PCB designs

- Test fixture PCBs

- Rigid-flex PCB

- Memory interfaces, e.g. DDR2, DDR3, DDR4

- Mixed-signal boards requiring noise / power isolation

- PCB Signal and Power Integrity: pre- and post-layout analysis and verification

- Impedance-controlled, transducer-interfacing, and sensitive signal designs

- RoHS/WEEE compliant lead-free designs

- Transition to manufacturing for high-yield, low-cost production, and IPC class 2 and 3 PCBs

- DFT (ICT coverage, JTAG test vector development, HALT, HASS)

- DFx for volume production (including BIST and test fixtures)

- Create PCB stack-ups to improve EMI/FCC issues

- PCB design DFM analysis (pre- and post- PCB layout)

- End-of-Life and cost-reduction redesigns

Our Projects