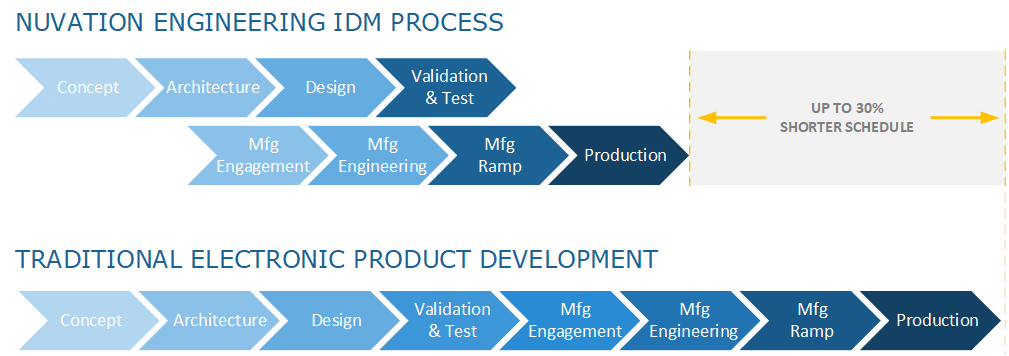

Nuvation Engineering’s transition to manufacturing approach differs from traditional electronic product development by beginning the process much earlier in the project. Using an approach we refer to as “Integrated Design to Manufacturing (IDM),” New Product Introduction (NPI) phases are run concurrently with traditionally earlier engineering phases, reducing the overall project schedule by as much as 30%.

How Do We Do It?

Traditional electronic product design approaches begin the New Product Introduction phases after extensive architecture, product design, and testing in order to mitigate risks that could lengthen the NPI effort. Nuvation Engineering mitigates these risks while compressing the project timeline by beginning the development of NPI test plans during the product architecture phase. We continue creating remaining NPI deliverables throughout the design and validation & test project phases. The result is a shorter project time and an increase in the quality of the finished product.

New Product Introduction Services

- Incorporating specific manufacturing requirements into the design process

- Establishing and optimizing an end-to-end supply chain to facilitate manufacturing

- Back-end design stages e.g. compliance certifications, packaging design

- Manufacturing engineering to prepare the design for volume production

- Defining fabrication/assembly/configuration, test, and quality systems

- Production pilot, ramp, and management of entire production process

Transition to Manufacture Services

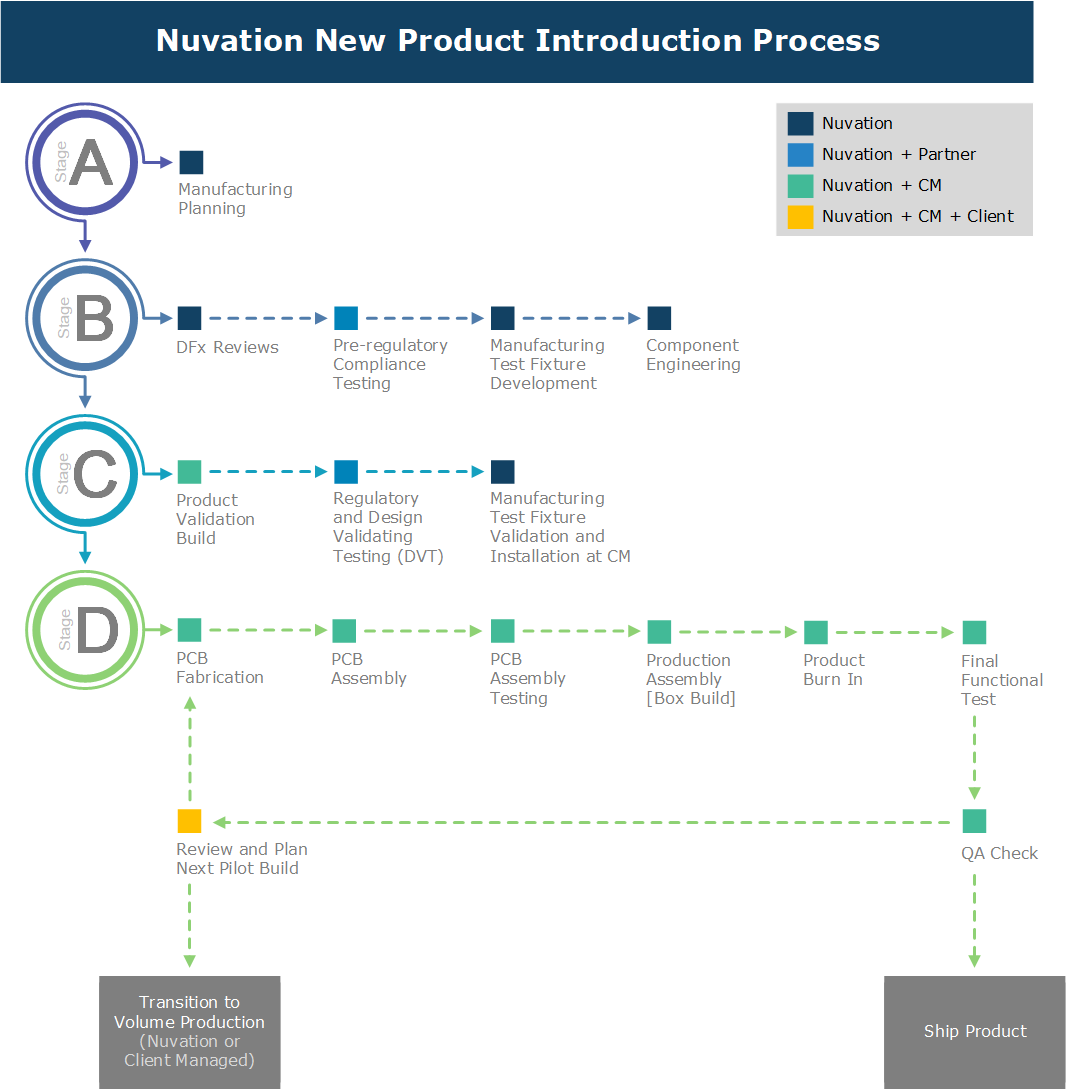

- Initial Manufacturing Engagement (IME) documentation to establish the appropriate test fixture design, product validation and product certification strategies:

- Manufacturing Test Plan (MTP)

- Manufacturing Test Verification Plan (MTVP)

- Manufacturing Readiness Test Plan (MRTP)

- Manufacturing Work Plan (MWP)

- DFx reviews to ensure testability and manufacturability of product

- Manufacturing test fixture software development based on test fixture design

- Manufacturing test fixture hardware design and fabrication based on test fixture design

- Manufacturing test fixture verification and installation at the CM responsible for product assembly

- Create a manufacturing test manual for product

- Coordination of the product packaging design

- Create an assembly guide for product

- Perform component engineering and hierarchical BOM management

- Oversight of regulatory testing

- Product Validation Testing

- Oversight of pilot production builds as a transition to volume production

Featured Projects

Low-Cost Portable Ventilator

Remote Health Care Monitoring

Blood Glucose Sensor