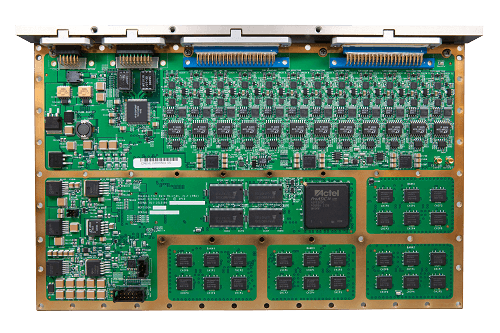

Nuvation Engineering designed and manufactured a 24-channel data acquisition system for a client in the aerospace industry. The design uses mainly COTS components, specifically selected for their radiation tolerant attributes. In addition to the design of the product, Nuvation Engineering developed and was responsible for the full IPC Class-3 manufacturing process, including: PCB assembly, AOI, X-ray, flying probe testing, epoxy staking, conformal coating, chassis assembly to controlled torques, chassis staking, many rounds of functional testing, and 40-hour HASS test.

Check out this video to learn more about the space data acquisition system we built.

Design Features:

- 24 independent channels of 16-bit, 150ksps Analog-to-Digital conversion

- Programmable 0-20mA current sources on all channels

- Programmable AC, DC, GND, or calibration-signal coupling on all channels

- Programmable gain amplifiers on all channels

- Programmable analog bandwidth limiting 100Hz – 27kHz, using 8th order filters on all channels

- Cutting-edge MRAM (Magnetoresistive Memory) and PRAM (Phase-Change Memory) for radiation tolerance

- Data-redundancy techniques to protect critical information

- Flash-based Microsemi FPGA with ARM Cortex soft-core processor

- ARM Firmware written in C++

- 20-Layer IPC/J-STD-001 Class 3 PCB Design

- Spacecraft data bus interface

- Radiation-hardened “kill switch” circuit

- Extensive self-diagnostic features and BIST routines

Services Provided: